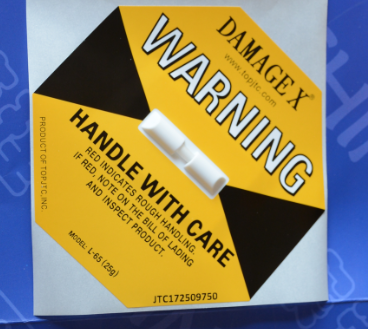

DAMAGE X® Anti damage warning label

[Product Brand]: DAMAGE X®

[Product Models]: 20G, 25G, 37G, 50G, 75G, 100G (G refers to gravitational acceleration)

[Product Specification]: 96MM * 96MM

[Packaging Specification]: 50 sheets\/box

The DAMAGE X brand damage warning label is affixed to the outer surface of the packaging, and records and displays the occurrence of abnormal vibrations through a color change of a special liquid glass tube embedded on the label. When the goods with vibration labels are subjected to abnormal vibrations during transportation, exceeding a certain limit G value, the color of the glass tube will change from white to red, quickly and permanently recording this abnormal vibration. By designing labels with different sensitivities, sensing and indication can be made from different vibration situations.

Keywords: vibration monitoring, vibration sensitivity, drop, logistics packaging and transportation

Reference rules for selecting Damage X anti damage warning labels:

The selection of indicator labels depends on the volume of the goods (length * width * height) and the weight of the goods; The larger the volume and the heavier the weight, the more sensitive the type of goods to choose. Other factors that should be considered& Flash;

& Middle; Packaging materials; When the packaging design is quite stable and the damage rate is low, the type with lower sensitivity can be selected;

& Middle; The precision of the goods themselves; If the goods are quite exquisite and have high transportation requirements, it is necessary to choose the type with high sensitivity;

& Middle; Product protection points and weight centers; When the product design is particularly special, such as being heavy on the head and light on the feet, the transportation requirements are also relatively high. Therefore, the type with high sensitivity should be selected

Volume of goods (cubic meters)

|

Weight (kg)

|

0.001-0.030

|

0.031-0.135

|

0.136-0.400

|

0.401-1.350

|

1.351+

|

|

0-4.5

|

green

|

green

|

orange

|

orange

|

red

|

|

4.6-11.25

|

green

|

orange

|

orange

|

red

|

red

|

|

11.7-22.5

|

orange

|

orange

|

red

|

red

|

purple

|

|

23-45

|

orange

|

red

|

red

|

purple

|

purple

|

|

45.5-112.50

|

red

|

red

|

purple

|

purple

|

yellow

|

|

113-450

|

red

|

red

|

purple

|

yellow

|

yellow

|

|

451+

|

--------

|

purple

|

yellow

|

yellow

|

yellow

|

Note 1. The packaging of the product and the texture of the packaging materials may affect the relationship between drop height and label discoloration;

2. This table is for reference only. It is recommended that users conduct actual drop tests based on their product packaging and other conditions to find the most suitable sensitivity label for product protection.

Placement rulesTechnical Specification Requirements for Anti Damage Labels

1.1 Placement principles

Usually, the anti damage label is placed on the packaging to the left or right, and the heavier the packaging, the lower the position of the label.

1.2 Placement of Green (100G) Label

The green anti damage label is generally affixed to the edge of the left or upper right corner of the packaging.

1.3 Placement of Orange (75G) Label

The orange anti damage label is generally affixed to the edge of the left or upper right corner of the packaging.

1.4 Placement of Red (50G) Label

The red anti damage label must be distinguished according to the weight of the packaging. For packaging less than 50Kg, it should be affixed to the upper left or right corner of the packaging near the edge. For packaging greater than 50Kg, it should be affixed at a height of 300mm to 600mm above the ground on the left or right side

Placement of 1.5 purple (37G) type labels

The purple anti damage label should be placed according to the following conditions:

If the weight of the packaging is between 20Kg and 50Kg, it should be pasted on the left or right edge of the packaging;

If the weight of the packaging is above 50kg, it should be pasted on the left or right side at a height of 300mm to 600mm above the ground;

For large packaging boxes or pallet shipping boxes, two labels need to be placed diagonally on both sides;

1.6 Placement of Yellow (25G) Label

The yellow anti damage label generally needs to be placed diagonally on both sides of two labels, and pasted on the left or right side at a height of 300mm to 600mm above the ground.

A note: Normal movement or bumps will not affect the label.

BApplication industry:

Automotive parts, medical equipment, bank ATMs, cabinets, network equipment, aviation equipment, wind power generation equipment, copiers, printers, instruments and meters, standard equipment, exhibition items, audio and video equipment, mechanical equipment, artworks, handicrafts, heavy furniture, solar power generation devices, precision processed products, and packaged items.

CSix major advantages:

& Middle- Reduce rough handling or illegal handling during transportation and storage.

& Middle- Provide unquestionable evidence to prove illegal handling.

& Middle- It can serve as a striking warning and deter illegal handling operations.

& Middle- Remind the recipient to check if the goods are damaged before receiving them.

& Middle- Promote auditable accountability throughout the entire transportation process of goods.

& Middle- Help identify problems throughout the entire supply chain from production, transportation to inventory.