principle

Vibration warning labelIt is a specially designed and very exquisite vibration response device, which is different from general mechanical or magnetic reaction mechanisms. Instead, it records and displays the occurrence of abnormal vibrations by changing the color of a glass tube filled with a special liquid embedded on a label. When the goods with vibration labels are subjected to abnormal vibrations, the color of the glass tube will change from white to red, quickly and permanently recording this abnormal vibration. By designing labels with different sensitivities, sensing and indication can be made from different vibration situations.

specifications

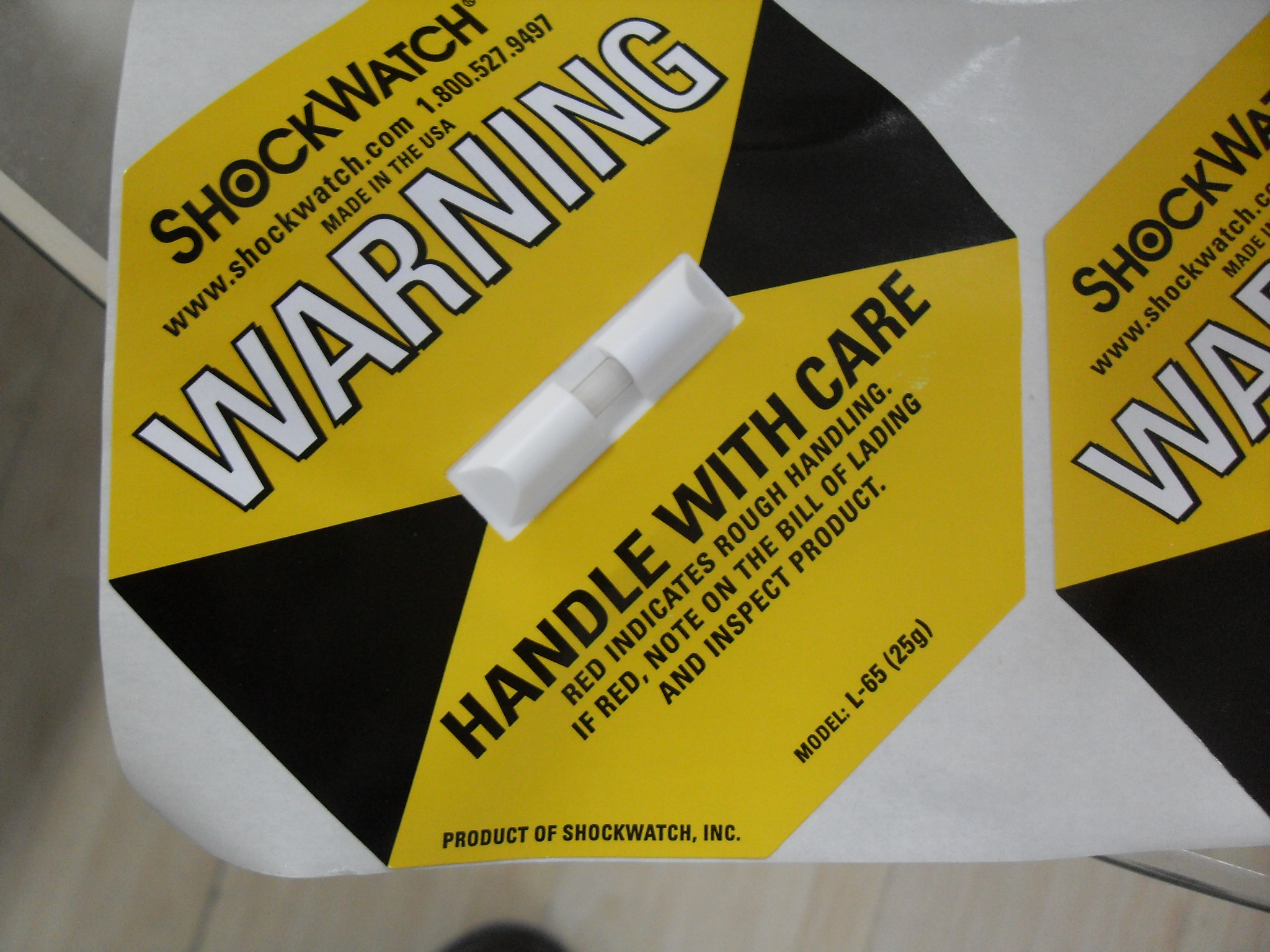

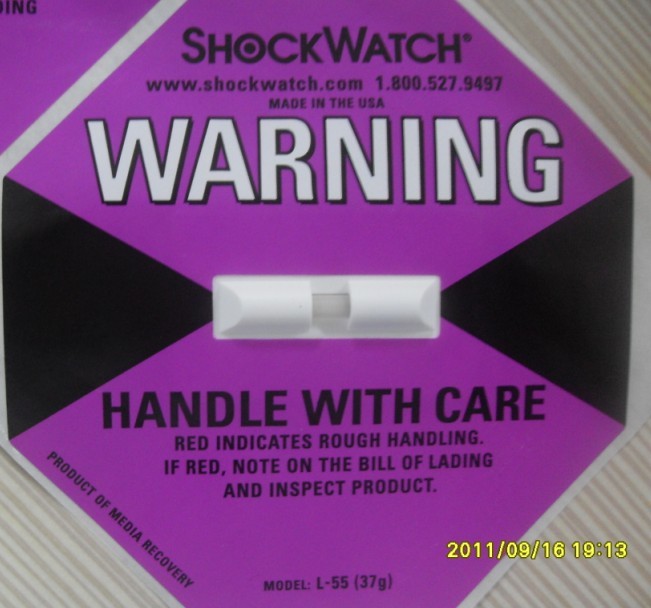

Shock Watch Label

Label size: 3.87&Prime& Times; 3.81″ (9.68cm× 9.68cm) octagonal shape

Crystal tube size: 1.35&Prime& Times; 0.38″ (3.43cm× 0.965cm) As indicated by 5 different colors, Shockwatch can provide 5 sensing areas. The different colors of yellow, purple, red, orange, and green indicate the different external impact forces that activate the label; Divided by the strength of sensitivity, yellow is the most sensitive and green is the least sensitive, arranged in the order of yellow, purple, red, orange, and green. The activation strength is indicated below the front of the label. The changes in these active labels indicate that when the packaging box is impacted in a certain plane and the packaging cannot effectively protect the product. Color guidance can help select the appropriate Shockwatch label model for the product.

Applicable scope

Vibration warningLabels are used to monitor and avoid excessive vibration or collision of goods during transportation. They are widely used in photocopying equipment, photography equipment, televisions, computers, DVs, electronic equipment, audio equipment, telephone communication equipment, automotive engines and components, glass products, precision components, furniture, lighting, pharmaceuticals, and biological products

choice

Rule: The selection of indicator labels depends on the volume of the goods (length * width * height) and the weight of the goods; The larger the volume and the heavier the weight, the more sensitive the type of goods to choose. Other factors that should be considered& Flash;

& Middle; Packaging materials; When the packaging design is quite stable and the damage rate is low, the type with lower sensitivity can be selected;

& Middle; The precision of the goods themselves; If the goods are quite exquisite and have high transportation requirements, it is necessary to choose the type with high sensitivity;

& Middle; Product protection points and weight centers; When the product design is particularly special, such as being heavy on the head and light on the feet, the transportation requirements are also relatively high. Therefore, the type with high sensitivity should be selected.